PRODUCT

CONTACT US

ZhengZhou Santow Agro Equipment Co., Ltd

Hotline:+86-371-5598 1030

Fax:+86-371-5598 1030

Phone:+86-187 6889 2838

Mail: sales@santow-agro.com

Poultry Farming & Battery Cage

Poultry Farming

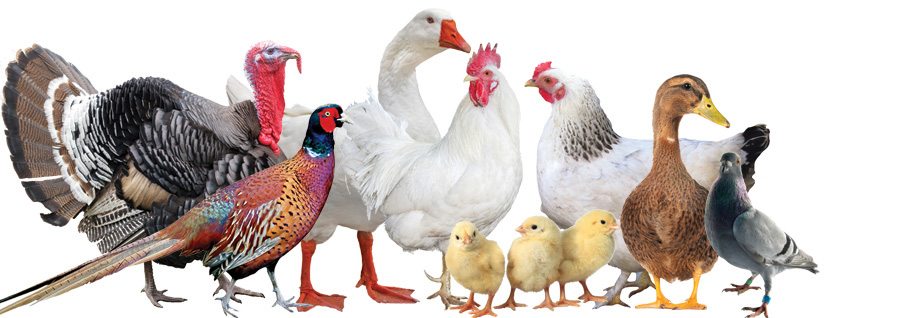

Poultry farming is the form of animal husbandry which raises domesticated birds such as chickens, ducks,

turkeys or geese to produce meat or eggs for food. Poultry, mostly chickens, are farmed in great numbers.

More than 60 billion chickens are killed for consumption annually. Chickens raised for eggs are known as

layers, while chickens raised for meat are called broilers.

In the US, the national organization overseeing poultry production is the Food and Drug Administration (FDA).

In the UK, the national organisation is the Department for Environment, Food and Rural Affairs

Also Read: Deep litter or cage system? Which gives the most profit on investment?

According to the World Watch Institute, 74 percent of the world's poultry meat, and 68 percent of eggs are

produced intensively. One alternative to intensive poultry farming is free-range farming using lower stocking

densities. Poultry producers routinely use nationally approved medications, such as antibiotics, in feed or

drinking water, to treat disease or to prevent disease outbreaks. Some FDA-approved medications are also

approved for improved feed utilization.

Commercial hens usually begin laying eggs at 16–21 weeks of age, although production gradually declines

soon after from approximately 25 weeks of age. This means that in many countries, by approximately 72

weeks of age, flocks are considered economically unviable and are slaughtered after approximately 12 months

of egg production, although chickens will naturally live for 6 or more years. In some countries, hens are force

moulted to re-invigorate egg-laying.

Environmental conditions are often automatically controlled in egg-laying systems. For example, the

duration of the light phase is initially increased to prompt the beginning of egg-laying at 16–20 weeks of

age and then mimics summer day length which stimulates the hens to continue laying eggs all year round;

normally, egg production occurs only in the warmer months. Some commercial breeds of hen can

produce over 300 eggs a year.

(Please scan QR Code for 720 Factory Panoramic View)

Battery cage

Poultry Farm using battery cages China (the below photo)

Also Read: Debeaking: How To Debeak Chickens?

The majority of hens in many countries are housed in battery cages. These are small cages, usually made of metal

in modern systems, housing 3 to 8 hens. The walls are made of either solid metal or mesh, and the floor is sloped

wire mesh to allow the feces to drop through and eggs to roll onto an egg-collecting conveyor belt. Water is

usually provided by overhead nipple systems, and food in a trough along the front of the cage replenished at

regular intervals by a mechanical system.

Battery cages are arranged in long rows as multiple tiers, often with cages back-to-back (hence the term). Within

a single barn, there may be several floors containing battery cages meaning that a single shed may contain many

tens of thousands of hens. Light intensity is often kept low (e.g. 10 lux) to reduce feather pecking and vent pecking.

Benefits of battery cages include easier care for the birds, floor-laid eggs (which are expensive to collect) are

eliminated, eggs are cleaner, capture at the end of lay is expedited, generally less feed is required to produce

eggs, broodiness is eliminated, more hens may be housed in a given house floor space, internal parasites are

more easily treated, and labor requirements are generally much reduced.

In farms using cages for egg production, there are more birds per unit area; this allows for greater productivity

and lower food costs.Floor space ranges upwards from 300 cm2 per hen.

Also Read: Chicken Care:Biosecurity and Health Management

EU standards in 2003 called for at least 550 cm2 per hen. In the US, the current recommendation by the United

Egg Producers is 67 to 86 in2 (430 to 560 cm2) per bird. The space available to battery hens has often been

described as less than the size of a piece of A4 paper.